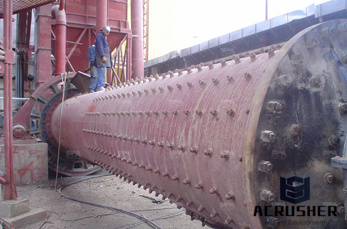

Ball Mill Critical Speed Working Principle YouTube

Jun 19, 2015· Besides dissipating a significant fraction of the total energy consumed by the mill (for example, the outer row of 50 mm diameter balls in a 4 meter diameter mill .

WhatsApp)

WhatsApp)

Jun 19, 2015· Besides dissipating a significant fraction of the total energy consumed by the mill (for example, the outer row of 50 mm diameter balls in a 4 meter diameter mill .

Overflow discharge Wet. Figure Effect of mill filling on power draft for ball In equation D is the diameter inside the mill liners and Le is the effective length of the mill including by the total charge Jb the fraction of the mill volume that. Get Price; effect of operational variables on ball milling Poli Monografias UFRJ

q is the charge volume in fraction of mill volume (40 % = ) nc is the mill speed in fraction of critical speed; Li and Di are length and diameter inside shell lining respectively (in meters) For a mill with more than m (7′) diameter the total power is obtained by dividing net power by

The flocculated solid fraction of olive mill wastewaters, obtained from two different olive oil extraction systems (FOMW1 and FOMW2) was composted, with olive leaves (OL) as bulking agent, by the static pile system (Rutgers). The dynamic of organic matter (OM) degradation during composting and its relationship with the basal respiration and fluorescein diacetate (FDA) hydrolytic activity, as ...

used is shown in Table 2, for a laboratory mill 6283 cm volume. Six monosize fractions (+, + +, +, 0 212+, + mm) were prepared and ground batch wise in a laboratoryscale ball mill for determination of the breakage functions. Each sample was taken out of the mill and dry sieved for

narrow size fractions of quartz and copper ore sizes (/+ mm; /+ mm; /+ mm and /+ mm) with the ball charge of different diameters (Table 1). The dry mill grinding has been conducted. The volume of grinding samples was equal to the volume of the interspaces of balls and the interstitial

Furthermore, the wheel kinematic characteristic is analyzed during hole helical millgrinding. The essential reason for reducing the hole exit defects is presented, which is changing the main feeding direction from axial to tangential. Meanwhile, the experiments of small hole helical millgrinding in 65% volume fraction SiCp/Al MMCs are carried ...

balances that can be used to estimate the fraction of a log recovered in a residue form. There are many ... and 73 present data illustrating the influence of mill source (residue type) and species on bulk densities. ... compacted chip volume of cubic feet is substituted.

The maximum travel dimensions of the Mill One are approximately 9 ¼" x 7 ¼" x 4" (235mm x 185mm x 100mm). The thickness of the materials you can cut is determined by the length of your cutting bits and the material type. The Mill One''s cutting volume rivals that of many other desktop CNC routers at a fraction of the cost!

Nov 10, 2002· Mass fraction vs. mole fraction vs. volume fraction. Another problem of the partsper notation is that it may refer to mass fraction, mole fraction or volume fraction. Since it is usually not stated which quantity is used, it is better to write the unit as kg/kg, mol/mol or m 3 /m 3 (even though they are all dimensionless).

Mar 01, 2014· Kim has presented batch grinding data for 10/14 mesh size fraction of limestone ground in a cm ball mill (mill speed, N: – (50–80% critical); ball size, d: cm; ball load, J: (corresponding to 50% filling of mill volume by static ball charge; particle load, U: (corresponding to filling of interstitial volume of ...

The volume of the waffle cone with a circular base with radius in and height 5 in can be computed using the equation below: volume = 1/3 × π × 2 × 5 = in 3. Bea also calculates the volume of the sugar cone and finds that the difference is < 15%, and decides to purchase a sugar cone.

The results suggested that a threeroll mill provided better mixing than a tworoll mill. Additionally, by heating the conglomerate slightly during mixing, lms were obtained with a smaller apparent critical volume fraction of silver particles. The results also indicated that a more uniform mixture was achieved through enhanced axial movement of ...

D = mill inside diameter (meters) J R = fraction of mill volume occupied by rods. Φ c = fraction of critical speed. The Rowland and Kjos equation indicates that power draw is a function of the fraction of the critical speed for the mill. Marcy mills are recommended to operate a peripheral speeds governed by the following relationship :

The results suggested that a threeroll mill provided better mixing than a tworoll mill. Additionally, by heating the conglomerate slightly during mixing, films were obtained with a smaller apparent critical volume fraction of silver particles.

The Influence of Sample Preparation on the Quantitative Analysis of the Volume Fraction of Martensite Formed in a 304L Trip Steel. Article (PDF Available) ... during step skin pass mill.

The relationship between conductivity of the paper coated with G/L, G/S, C/L, or C/S coatings and the volume fraction of conductive filler (graphite or carbon black) is shown in Fig. 2. The volume fraction was limited to no higher than about 30% for graphite and carbon black due to rheological issues.

Jan 01, 2016· J B = the fraction of the mill volume occupied by the bulk ball charge. If the masses of the rocks and balls were M R and M B respectively and V M the internal volume of the mill, then the fractional volume of mill occupied by the bulk rock and grinding media will be () J R = M R / ρ S V M × 1 1 − φ () J B = M B / ρ B V M × 1 1 − φ

Charge Volume. Mill should not be overcharged or undercharged; Overloading tends to accumulate fines at the toe of the mill which results in a cushioning effect. When the rock load is low, excessive balltoball contact retards the rate of breakage. The fraction of mill volume occupied by the ore, Jâ†"R:

The smock mill is similar to the post mill but has included some significant improvements. The name is derived from the fact that the body looks vaguely like a dress or smock as they were called. One advantage is the fact that only the top of the mill is moveable.

Let Jt be the fraction of the mill volume that is occupied by the total charge, Jb the fraction of the mill volume that. Get price; Optimization of mill performance by using. This test also shows that by feeding the mill with a too dilute pulp, the grinding zones between the media are not saturated, leading to high media wear rate.

Estimates the charge volume of a grinding mill based on the number of exposed lifters. By counting the number of lifters showing (during a mill shutdown) and comparing to the total number of lifters (including those buried in the charge) the fraction of the mill under the charge is determined.

Mar 29, 2012· mill residue, but at 98 to 99 percent utilization in each state, it was still highly utilized. Logging Residue: BBER''s logging utilization research clearly showed that logging residue as a fraction of mill delivered volume has continued to decline through time as land managers have progressive

During highspeed milling experiment in dry cutting condition when volume fraction was as high as 65% and small SiC grain size was 10 μm, Wang et al. [14] observed the effects of diamond grain ...

WhatsApp)

WhatsApp)